Description

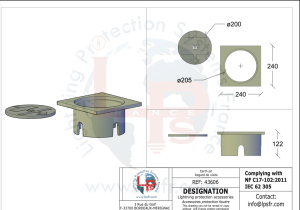

Cast iron inspection manhole

The cast iron inspection chamber with standard markings is an accessory used for the buried connections (Equipotential Spark Gap) between conductors in grounding systems. It is made of cast iron, ensuring its durability and robustness. Its dimensions are 110x250x250 mm and it weighs 7.495 kg.

The cast iron manhole plays an important role in grounding and lightning protection systems. It provides safe and protected access to underground connections, thus facilitating the maintenance and management of these systems. The cast iron manhole is particularly well-suited to areas subject to high mechanical stress (heavy loads)

Thus, the cast iron inspection chamber is a component used in grounding systems, primarily for the following reasons:

– Access to Underground Connections :

It provides access to underground electrical connections, such as junctions between different grounding conductors. This facilitates the inspection, maintenance, and troubleshooting of connections without the need to dig or disturb the ground.

– Connection Protection:

The plastic inspection chamber protects the buried connections (Equipotential Spark Gap) against physical damage, contamination by soil or debris, and exposure to moisture, thus contributing to their longevity and reliability.

– Durable Material:

The product withstands outdoor environmental conditions thanks to its design and material. It is also resistant to temperature variations and chemical attack from the soil.

– Ease of Installation and Use:

The inspection chamber is easy to install and use thanks to its design and material. Its cover can be opened to access the connections and closed to ensure continuous protection.

– Compliance with Standards :

The product complies with international standards such as EN 62561-5, IEC 62305 and NF C 17-102:2011. The cast iron inspection chamber ensures that the grounding systems meet safety and efficiency requirements.