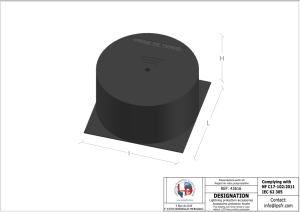

Description

Plastic inspection window

The plastic inspection chamber protects buried connections and Equipotential Spark Gap in lightning rod grounding systems and thus facilitates their maintenance. Made of polypropylene, with normative marking, dimensions of 200x200x100 mm and a weight of 0.360 kg.

Plastic inspection chambers are used in areas with low traffic of heavy loads (cars, trucks, forklifts, etc.)

The plastic inspection chamber is a component used in grounding systems, primarily for the following reasons:

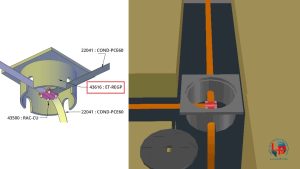

– Access to Underground Connections:

It provides access to underground electrical connections, such as junctions between different grounding conductors. This facilitates the inspection, maintenance, and troubleshooting of connections without the need to dig or disturb the ground.

– Connection Protection:

The plastic inspection chamber protects the underground connections (Equipotential Spark Gap connections) protect against physical damage and soil contamination. They also protect against debris and exposure to moisture, thus contributing to their longevity and reliability.

– Durable Material:

Made from polypropylene, a durable plastic, it is designed to withstand outdoor environmental conditions, including temperature variations and chemical aggressions from the soil.

– Ease of Installation and Use:

Thanks to its design and material, the inspection chamber is easy to install and use. Its cover can be opened to access the connections and closed to ensure continuous protection.

– Compliance with Standards :

By complying with international standards such as EN 62561-5, IEC 62305 and NF C 17-102:2011, the plastic inspection chamber ensures that grounding systems meet safety and efficiency requirements.