Managing a fleet of lightning rods often involves a complex trade-off between costly, sometimes unnecessary, annual inspections and the ever-present risk of an undetected failure between checks. How can you guarantee the operational integrity of your installations, especially after an intense storm, without increasing your operating costs? This is precisely the challenge addressed by predictive lightning rod maintenance . By leveraging connected technologies, this approach transforms a calendar-based preventive maintenance model into a proactive, intelligent strategy entirely driven by real-time data from your equipment.

This technical article explains how connected lightning protection systems are revolutionizing maintenance protocols. You will discover how this technological advancement not only drastically optimizes costs by targeting interventions only when necessary, but also ensures maximum safety through continuous 24/7 monitoring. We will discuss how to receive immediate alerts in the event of a lightning strike or anomaly, simplify multi-site management, and guarantee flawless regulatory compliance and traceability.

Key points to remember

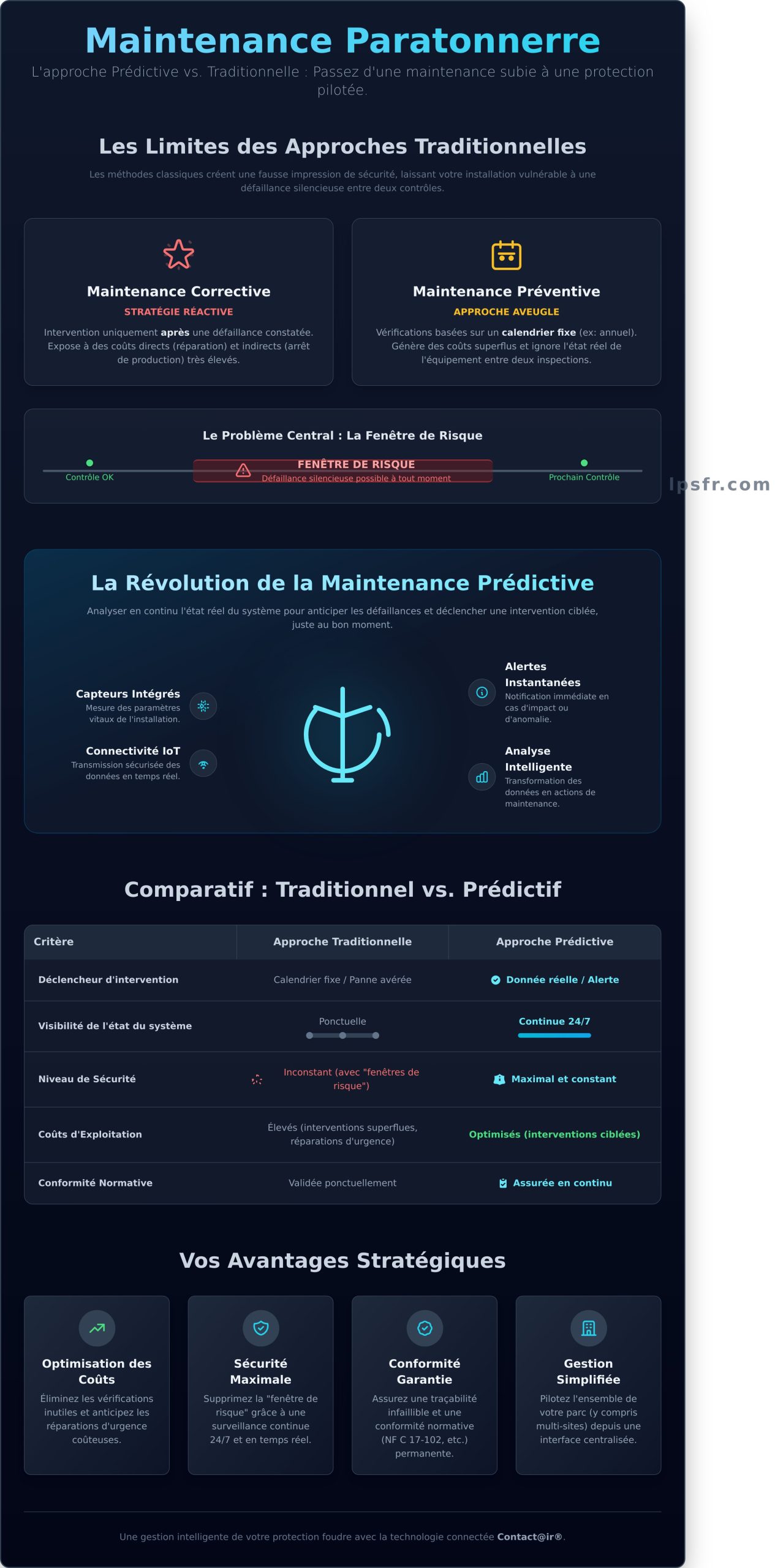

- Discover why traditional maintenance approaches (corrective, preventive) have limitations for truly effective lightning protection.

- Understand how predictive lightning rod maintenance analyzes the actual condition of your installation to anticipate failures before they occur.

- Evaluate the strategic benefits of such an approach: cost optimization, enhanced security and guaranteed regulatory compliance.

- Learn how connected lightning rods, such as with the Contact@ir® system, make this transition to intelligent management of your lightning protection possible.

The Limits of Traditional Lightning Rod Maintenance

Protecting a site against lightning relies on the ongoing integrity of its protection system. However, traditional maintenance approaches, while well-established, have structural weaknesses that can compromise this essential function. These approaches fall primarily into two categories: corrective maintenance, which is implemented after an incident, and systematic preventive maintenance, which operates according to a predefined schedule. Each of these methods leaves a significant portion of the installation without active monitoring, creating an unacceptable window of risk.

Corrective Maintenance: A Reactive and Costly Strategy

Corrective maintenance involves intervening only when a failure is detected, often following a visible lightning strike or proven physical damage. This reactive approach exposes the company to particularly high direct costs (repairs, equipment replacements) and indirect costs (production downtime, data loss). A down conductor severed by a third party, for example, will not be identified until the next storm, rendering the entire protection system inoperative at the crucial moment.

Systematic Preventive Maintenance: A Blind Approach

Systematic preventive maintenance is the most common approach, governed by standards such as NF C 17-102, which mandates periodic inspections. While necessary, this method relies on a fixed schedule (annual, for example) and treats each installation the same way. It can lead to a waste of resources by tying up technicians on perfectly functional systems. Its major drawback, however, remains the complete lack of visibility between inspections: a failure can occur immediately after an inspection, leaving the site vulnerable for months.

These traditional strategies create a false sense of security. The interval between inspections is a period of uncertainty during which the protection system can degrade without any warning signal. This fundamental shortcoming highlights the need for a shift towards predictive maintenance , which involves monitoring the actual condition of the equipment to anticipate failures. Without continuous monitoring, site managers expose themselves to critical risks.

- Silent failure: A component becomes non-functional without any visible external signs, rendering the protection ineffective.

- Undetected non-conformity: The system is no longer in compliance with current standards following a degradation.

- The obsolescence of protection: Blind faith in periodic inspection reports that no longer reflect the current state of the system.

The challenge, therefore, is to move from a logic of occasional checks to dynamic monitoring. This is precisely the role of predictive lightning protection maintenance : to ensure constant visibility and guarantee the system's operability in real time.

What is Predictive Maintenance Applied to Lightning Protection?

Predictive maintenance represents a major evolution compared to traditional approaches based on a fixed schedule. Rather than intervening at regular intervals, this method involves anticipating potential failures by continuously analyzing the actual state of a lightning protection system. The goal is to guarantee ongoing operational efficiency, in full compliance with lightning protection standards such as the NF EN 62305 series. This transition is made possible by the integration of smart sensors and IoT (Internet of Things) technologies, which collect, transmit, and analyze critical data to trigger intervention at the precise moment it becomes necessary: neither too early nor too late.

The Technological Pillars of Predictive Maintenance

The deployment of a predictive lightning protection maintenance relies on an interconnected technological ecosystem. Each component plays a vital role in transforming raw data into actionable insights.

- Integrated sensors: Installed on the lightning rod and down conductors, they measure vital parameters in real time such as the electrical continuity of the circuit or the physical detection of a lightning strike.

- Connectivity: A communication module transmits the collected data autonomously via long-range, low-power wireless networks, such as LoRaWAN or 4G/LTE.

- Software platform: Information is centralized on a secure web interface. It allows viewing the status of the entire fleet of installations, recording events, and generating reports.

- Algorithms and alerts: Algorithms analyze data streams to detect any anomalies or degradation. In case of a problem, the system automatically sends alerts (email, SMS) to maintenance personnel.

What indicators are monitored on a connected lightning rod?

Remote monitoring focuses on key performance indicators (KPIs) that directly reflect the system's ability to perform its protective function. Essential data collected by a connected lightning rod includes:

- Physical integrity of the lightning rod: The system can detect if the capture device is still in place and structurally sound after a storm or act of vandalism.

- Electrical continuity: This is the most critical parameter. The system constantly checks that the path from the lightning rod tip to the grounding electrode is not interrupted, thus ensuring the safe flow of lightning current.

- Lightning strike counting: Each lightning strike is recorded, dated, and characterized. This data allows for the assessment of the stress level experienced by the installation and the planning of thorough inspections if necessary.

- The battery status of the communication system: Monitoring the power supply of the connected box ensures that the monitoring device itself remains fully operational.

The Strategic Advantages of Predictive Maintenance for Your SPF

Adopting predictive lightning protection maintenance is a true revolution in lightning risk management. It allows you to move from a reactive approach, based on periodic checks, to a proactive, data-driven strategy. This transition generates measurable benefits in terms of cost, safety, and compliance, while significantly increasing the lifespan of your Lightning Protection Systems (LPS). For managers of multiple sites or sites with difficult access, this technology is a major operational advantage.

Cost Optimization and Operational Efficiency

Streamlining operations is one of the most immediate benefits. By continuously monitoring the system's status, interventions are only triggered by a genuine need, thus transforming maintenance management.

- Reduced travel: End of often unnecessary routine inspections. Technicians only travel based on specific alerts, saving time and resources.

- Optimized planning: Interventions are planned with an exact knowledge of the nature of the problem, improving efficiency and first-pass resolution rate.

- Preventing costly failures: A failing SPF can lead to material damage and critical production downtime. Early detection of anomalies prevents these catastrophic scenarios.

Enhanced Security and Reliability 24/7

The primary mission of a System Protection Facility (SPF) is to ensure uninterrupted protection. Predictive maintenance guarantees this continuous availability, eliminating periods of uncertainty.

- Constant visibility: You know at all times the operational status of each lightning rod in your fleet, directly from a centralized interface.

- Real-time alerts: An immediate notification is sent in the event of a lightning strike or component failure, allowing for maximum responsiveness.

- Eliminating the 'window of risk': The time interval between two manual inspections is a period of vulnerability. Connected monitoring eliminates this risk, ensuring that any anomaly is identified as soon as it occurs.

Simplified Regulatory Compliance and Traceability

Rigorous documentation is a requirement for insurers and regulatory audits. Predictive lightning rod maintenance automates this process, making it simpler and tamper-proof. The system automatically generates detailed reports and maintains a complete history of events (impacts, alerts, maintenance interventions). This approach, aligned with engineering best practices such as those described in reference guides like the IEEE Guide on Maintenance , provides tangible proof of the system's proper operational maintenance, drastically simplifying compliance procedures.

The Contact@irSystem: Predictive Maintenance by LPS France

Faced with the demands of service continuity and safety, reactive monitoring of lightning protection systems is no longer sufficient. LPS France has developed a cutting-edge technological solution to meet this need: the Contact@ir . This is a major advancement that transforms lightning rod management, shifting it from a reactive to a proactive approach. This technology is the cornerstone of true predictive lightning rod maintenance , ensuring unparalleled reliability and peace of mind.

The principle is to make any lightning rod, regardless of its brand or age, communicative and intelligent. Thanks to an autonomous transmitter, the health status of each installation is monitored in real time, 24/7. Any anomaly, whether it's a lightning strike or a break in electrical continuity, is instantly detected and reported.

How does the Contact@irsystem work?

The Contact@irtransmitter is a robust device designed for maximum efficiency and simplified installation. It attaches directly to the lightning rod or its down conductor and operates completely autonomously, without requiring an external power supply. Its purpose is to perform continuous system diagnostics.

- Simplified installation: The module can be installed in minutes on any existing or new installation.

- Long-range communication: It uses a low-bandwidth communication network to transmit data over long distances, even in isolated areas.

- Continuous diagnostics: The system continuously checks the physical and electrical continuity of the installation, from the tip of the lightning rod to the ground connection.

To learn more, Contact@ir technology in detail.

LPS MANAGER: Your Dashboard for Predictive Maintenance

All information collected by Contact@irissuers is centralized on a secure web platform: LPS MANAGER. This powerful tool offers a comprehensive overview and precise control of all your protected sites, transforming fleet management into a simple and efficient operation.

- Centralized visualization: An intuitive map interface allows you to locate and view the status of each installation at a glance.

- Real-time alerts: In the event of a failure or lightning strike, an alert is immediately sent by email or push notification, allowing for rapid intervention.

- History and reports: Access the complete history of events (impacts, alerts, maintenance) for each site, facilitating analysis and traceability.

LPS MANAGER is an indispensable ally for installers and asset managers who wish to optimize their operations, reduce their costs and guarantee flawless protection of their assets.

Towards Proactive and Intelligent Lightning Protection

In conclusion, the era of reactive maintenance is over. Traditional lightning protection system (LPS) inspections, while essential, have limitations that can compromise safety between inspections. The transition to a proactive approach is a strategic necessity to guarantee seamless protection, ensure business continuity, and optimize maintenance costs.

Adopting a predictive lightning protection maintenance , embodied by cutting-edge technologies, is the most reliable response to these challenges. The Contact@ir from LPS France represents this major advancement, offering continuous, real-time monitoring of the integrity of your installations.

Choose a patented, French-made technology whose performance has already been validated on thousands of equipped sites worldwide. Fully compatible with all types of lightning rods, this solution ensures an effective and lasting upgrade to your security. Don't leave the protection of your assets to chance any longer.

Stay ahead of lightning risks. Request a demonstration of the Contact@ir and LPS MANAGER solution. Anticipate failures and ensure optimal protection for the future.

Frequently asked questions about lightning rod monitoring and maintenance

Does predictive maintenance completely replace mandatory visual inspection?

No, predictive lightning rod maintenance does not replace but complements the mandatory visual inspection. The NF C 17-102 standard mandates periodic checks, which remain compulsory. The remote monitoring system provides continuous diagnostics of the lightning rod's functional status between these inspections. It provides immediate alerts in case of failure or a lightning strike, enabling targeted and rapid intervention, but it does not replace the physical examination of conductors and grounding systems.

What is the autonomy of a system like Contact@ir®?

The Contact@irsystem is designed for extended battery life, typically exceeding 10 years under standard operating conditions. It is powered by a high-performance internal battery, optimized for low energy consumption. This longevity ensures reliable and continuous monitoring without requiring frequent maintenance of the transmitter itself, which is particularly advantageous for hard-to-reach sites or critical installations requiring uninterrupted protection.

Is the system compatible with lightning rods from other brands?

Yes, although the Contact@irsystem is natively integrated into LPS Francelightning rods, it can be installed on Early Streamer Emission (ESE) lightning rods from other brands. This compatibility is ensured by a specific adapter kit that allows the transmitter to be mounted and guarantees the electrical continuity necessary for its proper operation. This flexibility allows for the modernization of an existing installation and provides the benefits of remote monitoring without replacing the entire lightning arresting system.

How is data transmitted from an isolated site without a mobile network?

For sites lacking traditional mobile (GSM) coverage, data transmission is carried out via low-bandwidth, long-range networks such as LoRaWAN. This communication protocol is specifically designed for connected objects (IoT) and ensures excellent penetration even in remote areas. In cases of extreme isolation, satellite communication solutions can also be deployed, thus guaranteeing that the status of the lightning protection system remains continuously monitored, regardless of its geographical location.

What is the return on investment of a predictive maintenance system?

The return on investment for a predictive lightning protection maintenance is rapid and tangible. It materializes in the drastic reduction of operating costs: travel for routine checks is optimized, as interventions are only triggered by an alert. Furthermore, by guaranteeing the continuous operability of the system, it prevents costs associated with production downtime, equipment damage, and data loss resulting from a lightning strike on a non-functional installation.

Is installing a communicating transmitter complex?

Installing a communicating transmitter like the Contact@iris a quick and easy procedure for a qualified professional. The transmitter attaches directly to the lightning rod, without requiring complex wiring. The module is then activated securely, often via a dedicated mobile app. While the operation is technically simple, it must be carried out by a trained installer to guarantee a perfect electrical connection and the overall compliance of the installation.