Lightning rod lightning protection systems, including down conductors, are designed to direct electrical discharges from lightning safely to the ground, reducing the risk of damage to buildings and people. The most common materials used in their construction include:

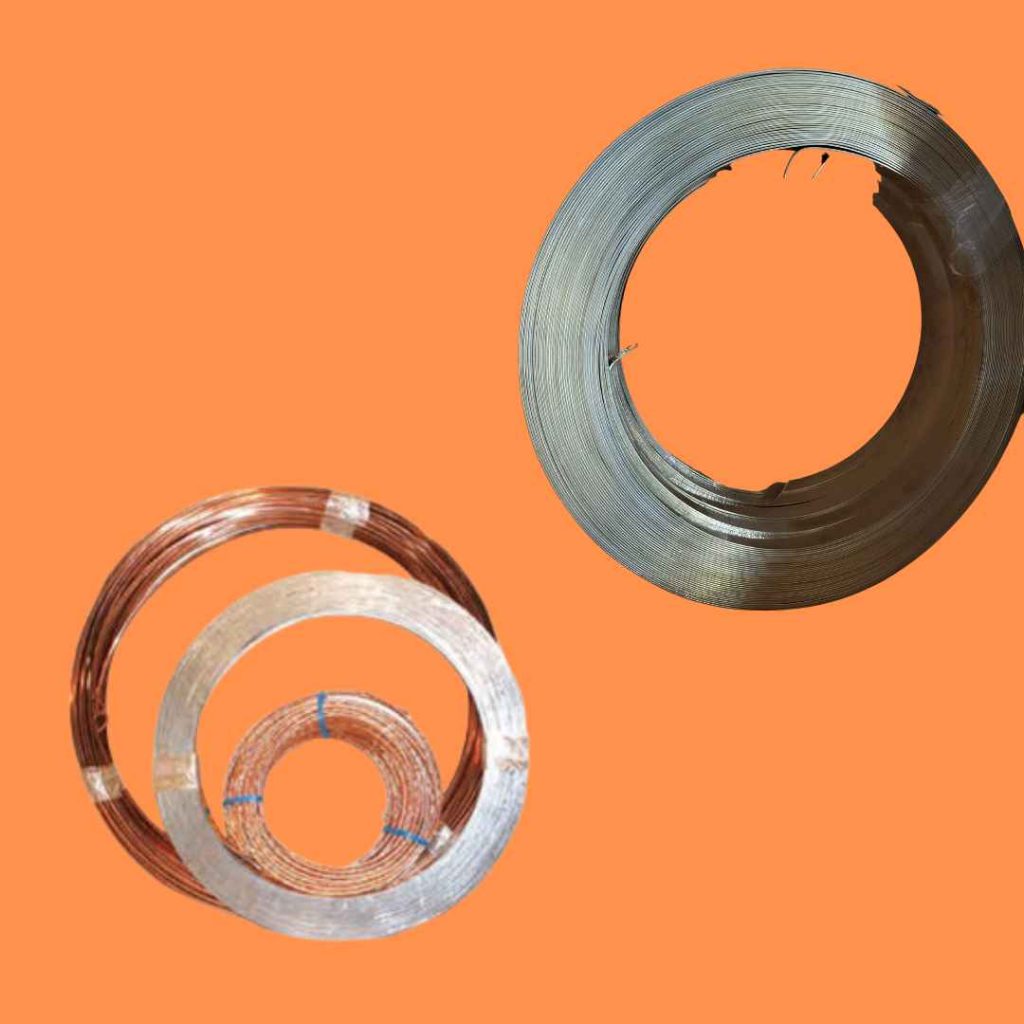

- Copper: Copper is one of the most traditionally used materials for lightning protection systems due to its high electrical conductivity and corrosion resistance when tinned. Copper conductors provide excellent durability and performance in various weather conditions.

- Aluminum: Aluminum is another material commonly used in the construction of lightning rod lightning protection systems. It is less expensive than copper but still offers high electrical conductivity and corrosion resistance, making it a wise choice for lightning rods.

- Galvanized Steel: Galvanized steel is often used for the structural components of lightning rods, such as poles and brackets. It is coated with a layer of zinc to protect against corrosion. Although less conductor than copper or aluminum, it is often used for its robustness and weather resistance.

- Stainless Steel: Stainless steel is used in some lightning rods because of its exceptional resistance to corrosion. It is more expensive than other options but may be preferable in very corrosive environments, such as coastal or industrial areas.

The choice of material often depends on the specific project requirements, available budget, geographic location and local environmental conditions.